When Illinois Institute of Technology (IIT) looked at the future of its campus energy systems, it faced a familiar challenge: aging infrastructure, rising electricity costs, and an urgent need to cut carbon emissions. Instead of simply replacing boilers and turbines, IIT chose a transformative path forward—partnering with Energy Tech Partners, including Energy and Water Development LLC (“EnWaDev), to deliver a state-of-the-art Combined Cooling Heating and Power (CCHP) aka tri-generation plant.

From Outdated Combustion to High-Efficiency Tri-Generation

Since the 1990s, IIT had relied on natural gas fueled combustion turbines with waste heat recovery to meet its power and heating needs. Over time, however, those turbines became inefficient and poorly matched to the campus load profile. Furthermore, the turbines stopped generating power. A major overhaul would have been costly—and still left the university dependent on technology unsuited to current and future energy (power, heating and colling) needs.

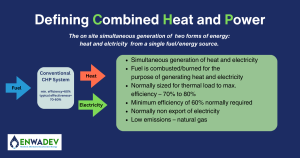

The new solution? A tri-generation system that generates electricity on-site and captures and reuses waste heat. In summer, waste heat is converted into chilled water for cooling. In winter, it’s transformed into hot water for heating. By capturing what would otherwise be wasted energy, the system achieves 70% or greater overall efficiency—nearly double the efficiency of traditional power generation.

Reducing Carbon Emissions by at least 35%

Sustainability was a key project goal. The tri-generation plant is projected to cut Illinois Tech’s carbon emissions by 35–40%, displacing both grid electricity and natural gas previously used in boilers. In addition to CO₂, other pollutants like carbon monoxide, volatile organic compounds, and particulates will also be reduced.

Even better, the natural gas reciprocating engines comprising the tr-generation system are future-ready. With modest modifications, they can run on renewable natural gas (RNG), hydrogen blends, or other low-carbon fuels as they become economically viable—further lowering the university’s environmental footprint.

Shielding Against Rising Energy Costs

IIT’s electricity bills were climbing sharply, in part due to capacity pricing and rising demand charges. The tri-generation system provides an elegant solution: generate power behind the meter. By producing at least 95% of campus electricity on-site, the university avoids costly utility delivery fees, capacity charges, and taxes—stabilizing costs for decades to come.

A long-term utility agreement, structured over 40 years, ensures that the capital investment pays for itself through savings. With rising grid costs, the project’s economics are expected to improve even further over time.

A True Public-Private Partnership

Illinois Tech followed the example of universities like Ohio State and Iowa, pursuing a long-term partnership model to ensure success. After soliciting multiple proposals, the university selected Energy Tech Partners with EnWaDev as a key member. EnWaDev conceptualized and designed the tri-generation project plus co-developed the project from Request for Information (RFI) to signed contract

“Suresh [Jambunathan of EnWaDev] has been very available, showing his expertise not just in the design and concept, but also in the financial payback and ROI. It’s rare to find a partner that understands the engineering, the operations, and the economics at the same time.” – Illinois Tech

Looking Ahead

The project positions Illinois Tech as a leader in campus sustainability and energy independence. By combining efficiency, resilience, and flexibility, the tri-generation plant will power the university into the future—delivering reliable electricity, heating, and cooling while reducing costs and emissions.

For EnWaDev, this project exemplifies our mission: designing and delivering energy solutions that work today while preparing for the cleaner, smarter energy systems of tomorrow: Resilient, Affordable, Decarbonized Energy (RADE)!